![]()

The hydrodinamic RINGO speargun of the manufacture SOS.

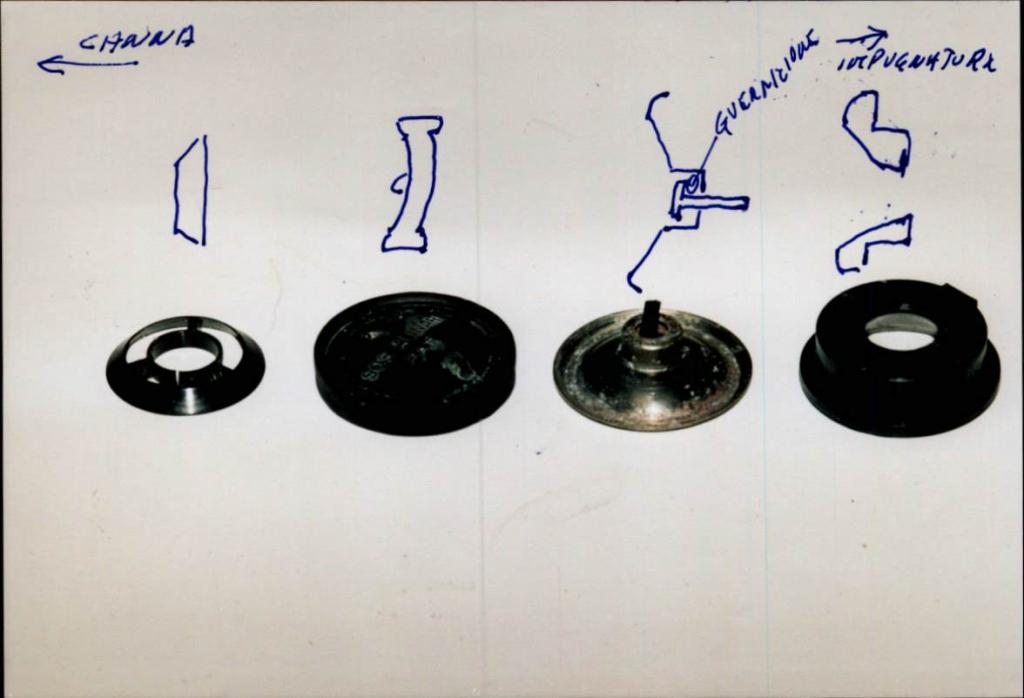

1. plastic pistol grip, 2. domed and reverse curve rimmed metal disc seating plate for trigger valve (at centre) and for diaphragm firing valve clamping (at periphery) backed by cylindrical plastic moulding with concave front face to match curvature of domed metal plate, 3. groove edged locating ring to assist locking of front face of rear shoulder step on polyurethane sleeve into outer tubular cover, 4. forward bulkhead of vented outer body section to cup and lock front end of polyurethane sleeve onto inner barrel tube, 5. split locking rings (x2), 6. realigning "spring" for tilt type trigger valve, 7. trigger valve, 8. rubber packing (seal) of trigger valve, 9. vented (longitudinal slots at each end) outer cover tube, 10. plastic trigger, 11. trigger pivot pin, 12. transverse safety slide, 13. front nose cone with line wrap hook, line attachment position and front aiming sight, 14. screw, 15. nut, 16. forward barrel floatation elements, 17. inner barrel tube, 18. "Vulkollan" polyurethane sleeve "lung", 19. windowed centralizing disc providing support at rear entrance to polyurethane sleeve, 20. firing "releasing" valve rubber diaphragm has small outer leak path hole (not indicated on diagram), 21. shooting line rear clip, 22. shaft tail seal attachment screw, 23. "Vulkollan" polyurethane shaft tail seal (also line slide stop), 24. spear shaft, 25. line slide, 26. dual flopper spear tip. (circlip on inner barrel between forward bulkhead and ōVulkollanö sleeve not numbered)

Gun held together by forward bulkhead engaging circlip in groove on inner barrel, outer cover engaging forward bulkhead with split ring in matching locating grooves and plastic pistol grip threaded into rear of cover. "Vulkollan" sleeve clamped to diaphragm between second split ring in outer cover and thread on rear grip.

The "Ringo" is not like the RPS-3 gun, the inner barrel is only open at the rear end and has no holes drilled in the barrel wall. Functionally the "Ringo" works like the "Hydra", but has the rubber bladder surrounding the rear end of the inner barrel. Only the rubber bladder has no compressed air on the outside to give pressure to the water inside the gun, instead this pressure is created by stretching the thick wall of the bladder which is a sleeve cast from "Vulkollan" polyurethane. This is the gun that I mentioned to you many years ago, only I did not then know its name or exactly how it worked. All I knew is that the rear handle gun had a rubber bladder or sleeve which stretched radially as water was forced into the gun and was produced by SOS in Italy. I am attaching a document which I have prepared for the "Deeper Blue" forum showing the internal layout.

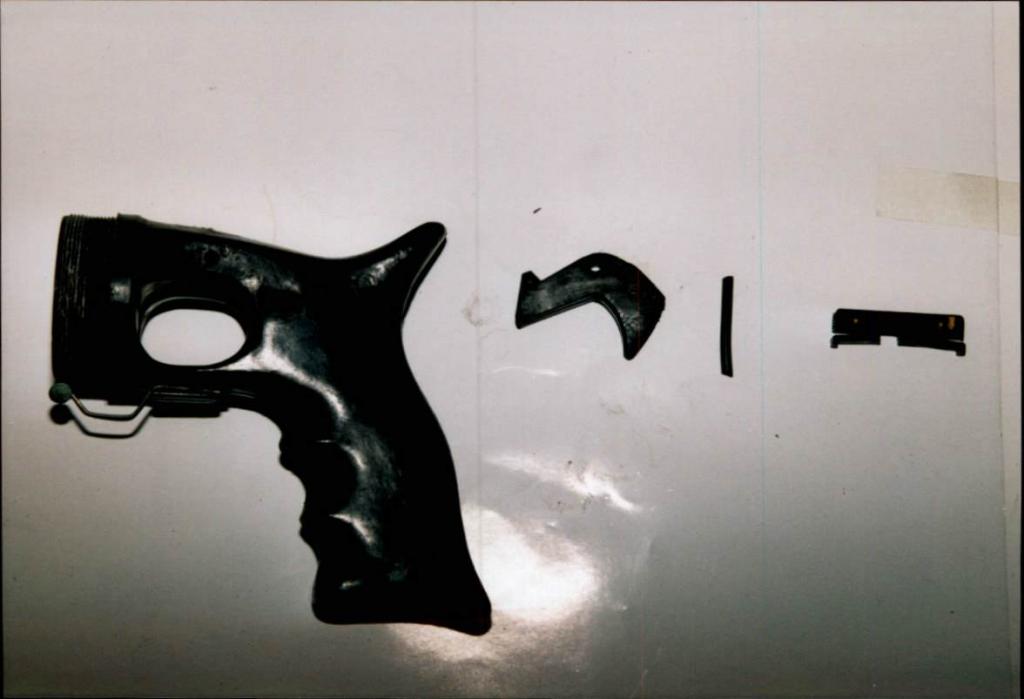

Only photos I have of complete "Ringo" speargun are attached. forward section of gun has foam floatation (black barrel), rear section covers the "Vulkollan" polyurethane sleeve (blue cover with slots to allow water to flow in and out as polyurethane sleeve expands and contracts).

Think of the "Ringo" as a complete water gun, it has no air inside it anywhere when used underwater. The trigger system is a hydraulic lock servo or pilot valve operation relying on water being incompressible, exact same principle as your "Aquatech" speargun uses. No compressed air, just that polyurethane sleeve creating pressure as you stretch it radially along its cylindrical length by over filling it with water pushed down the inner barrel. There are two water valves, the pilot valve right in front of the pivoting trigger and the "firing" (releasing) valve rubber diaphragm that bows (parabolic shape when viewed in cross section) backwards and forwards depending on the pressure differentials existing across the faces on either side of it (the black part, number 20). The trigger mechanism is something like a servo or pilot valve operated scuba diving regulator diaphragm, only the diaphragm operation in the "Ringo" opens the inner barrel at the rear instead of a compressed air supply coming through a low pressure hose in a two-stage scuba regulator. I have my doubts about the efficiency of the "Ringo" gun due to energy losses in the polyurethane sleeve's expansion and contraction process, but it will depend on the physical properties of the "Vulkollan" material and at what degree of stretch does it stop performing as an ideal spring with only relatively small energy losses. I think a good indication of the gun's suitability for spearfishing is that the gun is no longer manufactured! But this is something which I hope to find out by someone posting a message based on their own personal experience with the gun.

I think the best feature of the "Ringo" gun is the rear handle position with respect to the body of the gun, very high up.

Some more information on the "Ringo" series of spearguns. The inner barrel diameter was 6.5 mm, which is very small. The longest "normale" version was about a metre long and had a working course for the spear of 85 cm. There are two shorter models, the "corta" (which is the gun shown in the above photos) and a pistol sized "cortissima". The difference between models is in the length of the black forward barrel section which contains foam elements surrounding the inner barrel, the "normale" forward barrel is about twice the length of the one on the "corta" and the "cortissima" has virtually no forward barrel at all, just a short projection to the plastic muzzle. Barrel assemblies were available as accessories to covert "normale" guns to the two shorter models, as were spears including durallium versions for above water use. An inox stainless steel shaft was available for the "normale" gun to replace the standard steel shaft. The rear pistol grip and "Vulkollan" sleeve housing was identical in all models, hence with multiple spear insertions they all contained the same volume of water at maximum radial stretch of the "Vulkollan" sleeve. The "normale" gun's spear could be pumped twice, the "corta" three times and the "cortissima" six times according to the instructions. There are some small breather holes located approximately 10 cm. from the mouth of the inner barrel, so the gun can suck in extra water without pulling the spear completely out of the inner barrel (shown on the layout diagram if you look closely at the pdf attachment). That would give the same hydrostatic pressure inside all guns regardless of their length, but of course the spear was propelled for shorter distances inside the barrel of the smaller guns and the extra volume of water above that required to clear the spear from the barrel did nothing once the spear was gone. Higher internal pressure achieved by spear pumping was essentially increasing the circumferential stretch of the wall of the polyurethane sleeve, rather like pulling a rubber band progressively further back on a band gun. The releasing valve hydraulic trigger mechanism makes this possible as until you pull the trigger it works like a one-way valve, letting water in, but not out. Aquatech "Dnepr" and "Black Sea" speargun trigger mechanisms operate the same way, only there the hydraulic valve is a piston and not a rubber diaphragm.

The diameter of the black forward outer barrel tube was 44 mm and the diameter of the blue outer cover with four slots at either end was 60 mm, so the guns were not slim by any means. At 6.5 mm inner barrel diameter, half that of contemporary pneumatic guns with 13 mm inner barrels, the "Ringo" fired a very slim shaft which in the era of 8 mm and 9 mm shafts probably seemed barely adequate. I suspect that aspect limited their appeal, plus to achieve maximum hydrostatic pressure the final push effort on the shaft was 75 kg, probably enough to bend it if it was not deeply inserted into the gun by that stage.

The guns were guaranteed for 5 years which was cited as a first for spearguns and with few components could be quickly disassembled. I wonder what the service life of the "Vulkollan" sleeve was, maybe the guarantee period is a clue.